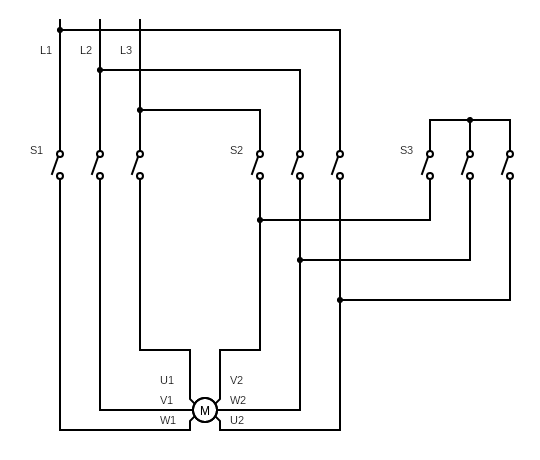

STAR-DELTA 0-Y-Δ CIRCUIT SWITCH: OPTIMIZING THE START-UP OF INDUCTION MOTORS

In world of industrial electrical engineering, the efficiency and reliability of drive systems are crucial. Start-up of induction motors, especially high-power ones, requires limiting of starting currents that can negatively affect the supply network and the motor itself. One of popular and proven solution is the use of a star-delta 0-Y-Δ system, which requires appropriately selected contactors.